Basically any liquid can be used as a medium for power transfer. But in the hydraulic system requires specific requirements as discussed previously in connection with the construction and operation of the system. Broadly speaking hydraulic fluids are grouped into two general categories:

a. Hydraulic oil (hydraulic oils)

Hydraulic oil based on mineral oil is usually used extensively in tooling machines or also industrial machines.

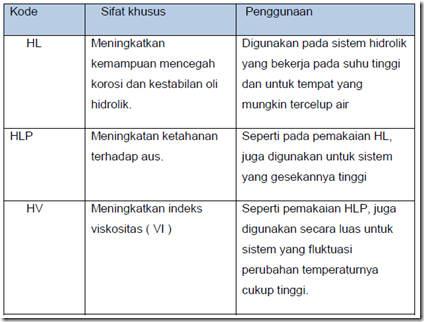

According to the standard DIN 51 524 and 512 525 and in accordance with the characteristics and composition of hydraulic oil divided into three (3) classes:

– Hydraulic oil HL

– Hydraulic oil HLP

– Hydraulic oil HV

The coding with letters such as the above meaning is as follows: For example, the hydraulic oil with the code: HLP 68 means:

H = Hydraulic oil

L = code for oil additives (additive) to improve corrosion prevention and / or an increase in the age of oil

P = code for additive which improves the ability to receive the load.

68 = oil viscosity level (see table at HO 4)

Table specific properties and suitability of its use

b. Fire-resistant hydraulic fluids (Low flammabilty)

What is meant by a hydraulic fluid fire resistant hydraulic fluids that are not easily or can not burn. This kind of hydraulic fluid used in the hydraulic system places or machines that the fire risk is high enough, such as:

– Die casting machines

– Forging presses

– Hard coal mining

– Control units for power station turbines

– Steel works and rolling mills.

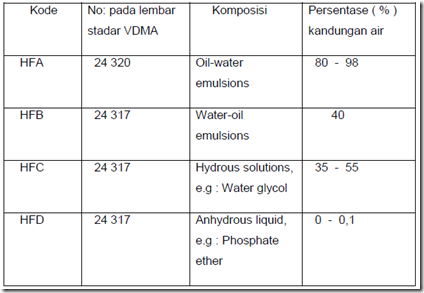

Basically, fire resistant hydraulic fluid is made from a mixture of oil with water or synthetic oil.

Table types of fire-resistant hydraulic fluids

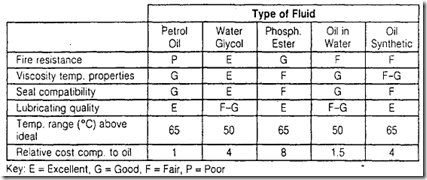

A comparison table between the various hydraulic fluids

Hydraulic fluids including expensive items. Treatment less or even no good against hydraulic fluid will further add to the high price of hydraulic systems. Whereas if we obey the rules on the treatment / maintenance of hydraulic fluid, the liquid damage or damage to system components will be avoided and hydraulic fluid and the system will be more durable.

Free maintenance of hydraulic fluid

- Keep hydraulic fluids (drums) in a dry, cool and protected (from rain, heat and wind).

- Be sure to use hydraulic fluid that is completely clean to supplement or replace the hydraulic fluid into the system. Also use clean equipment to include it.

- Pompakanlah hydraulic fluid from the drum to the hydraulic tank through a filter (pre-filter).

- Monitor (monitor) and check regularly and continuously conditions of hydraulic fluid.

- Arrange in such a way that only the meeting point of the tank filling that is used for charging the hydraulic fluid.

- Make the hydraulic fluid change intervals such that oxidation and damage liquid can be avoided. (Check with the supplier of the hydraulic fluid)

- Prevent lest contamination, use air filters and oil filter are good.

- Prevent heat / overheating, if necessary plug cooling (cooling) or when terjad, check the cause of the disorder, or post un-loading pump or excessive resistance.

- Correct immediately in case of leakage and assign a maitenance man trained.

- When replacing hydraulic fluids (what more if different hydraulic fluids), certainly-the-seal that seals the components and fit with new fluid. Similarly, the entire system must be rinsed (flushed) well and really clean.

So monitoring or monitoring of hydraulic fluid needs to pay attention to the above guidelines in addition must pay attention to the work environment or the hydraulic fluid storage environment.