Maintenance on the hydraulic system is very important, because it will greatly determine the operational life of each component, but on the maintenance of this hydraulic system usually lies in fluid, safety valve-valve; piston; motor and so on. On fluid maintenance is highly dependent on the condition of the oil, the oil change is cultivated after certain hours of use and not to wait for several months, because in this case every time the fluid system is used it is of course the oil will become dirty (contaminated), either by the particles from the outside (dust, dirt, rubber flakes, etc.), as well as dirt from the inside (due to friction).

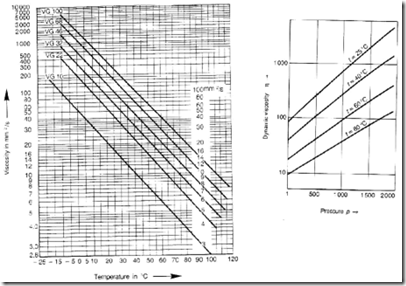

For that oil should be stored on a closed Resevoir and a clean place, if we want to clean and refill the oil back into the reservoir should be used a clean mouthpiece and a fine filter. This is to prevent particle-enhancing substances and sludge from entering the reservoir. Here is a graph of the relationship between fluid viscosity and recommended working pressure and operating temperature.

Filter Maintenance

As we know filter function is to filter the dirt, sludge, and others so as not to go into the hydraulic system. Because the filter capacity is very limited, the filter is only able to maintain the actual oil quality for a certain time, so try to clean the filter by removing the filter and then washing it with a certain liquid, then sprayed with air, in order to insure the particles in the liquid can come out with the help of air pressure.

In addition, at the time of installation of the filter must be considered how the installation sealnya, where seal also must be in place so that the maximum filtering is produced. If the machine does not have a plug sieve indicator (filter clogged), please note the maintenance intervals shown in the instructions for use