The maintenance of equipment is a very important activity because it can slow down the damage, maintain the functionality / usability furnace, durability, and safety. Therefore, periodic and scheduled maintenance activities must be carried out. Maintenance of equipment aimed at:

- Extend the life of equipment

- ensure readiness equipment

- Guarantee the efficiency and effectiveness

- Ensure the safety of users

Programmed maintenance will greatly facilitate control over the readiness of equipment to be used. To that end, we encourage all equipment, especially equipment powered by electricity must be equipped with a user card, care card / maintenance, and repair card. Similarly, the electric furnace. Electric furnace maintenance require precision and accuracy because it will determine the final result of combustion.

1 Tool

1) Vacuum Cleaner

2) Brush

3) Multi Tester

4) Brush Wire

2 Materials

a) Styrofoam

b) Paint heat resistant and rustproof

3 Electric Furnace Maintenance Procedures

a) In the combustion process, at the stage preheating furnace door should not be closed tightly (opened slightly) and ventilation holes and the hole reconnaissance (spy hole) left open to a temperature of 600 o C. This meant that the water vapor from the ceramic body or glaze can be out so as not to create rust or porous metal furnace construction.

b) Cleaning the inside of the furnace from dust or dirt fine shards of ceramic objects using a vacuum cleaner.

c) Patching wall, pedestal, and the roof is cracked or eroded by the refractory cement by way of wetting the cracks with water in the brush before filling done.

d) replace the refractory bricks soon broken by an adhesive refractory cement.

e) Avoid materials that easily produce smoke in the combustion process.

f) Avoiding the use of an electric furnace for the combustion process of reduction.

g) Checking electric furnace coil as follows:

- using styrofoam

– Connecting the electrical flow in the furnace to turn on the switch.

– Attaching styrofoam on the coils. If the coil is functioning then stryrofoam will melt because of the heat, otherwise if stryrofoam not melt, it means the coil is broken or there is no power.

- using multitester

– Rotate the switch in position ohms.

– Connecting the two cables multitester at each end portion of the coil. When the multimeter needle moves to the right, then the coil to function, but when the needle multimeter does not move, then the coil broke. Preferably a coil that has broken off immediately repaired or replaced with new ones.

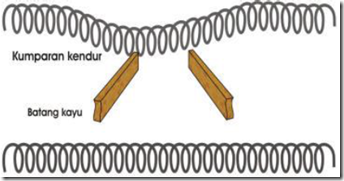

h) The coils are loose and out of place put back by turning on the furnace so that the coil a little hot, then using two sticks of dry wood, push the coil in place. This must be done carefully because of the nature of the coil is easily broken.

Figure 43. How to fix a loose coil.

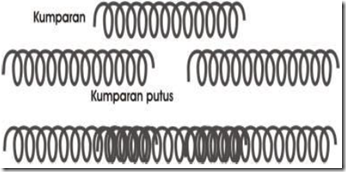

i) coils that broke spliced by adding a coil that has a diameter of the coil and the coil diameter of the same. This should be done in a state of furnace off (no electricity)

Figure 44. How to connect the coil broke loose.

j) Clean the electric furnace are corroded by using a wire brush, then repainted with a heat resistant paint and rust resistant.