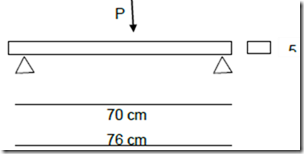

a) Examination of wood bending strength

Tools and materials required:

o machine press / pull with equipment

o Dial manometer

o ruler measuring / roller meter

o Wood with a size of 5 x 5 x 76 cm

Inspection Method

o Prepare equipment of the flexural strength at press machine

o Put the timber on a machine with a distance of 70 cm pedestal.

o Give the burden on the middle of the wood with a speed of 2.5 mm per minute with a deviation ± 25%.

o Note the loading and decrease deflection.

o Read load (P) if the timber has suffered broken and not able to be burdened.

o Hitng flexural strength by the formula 3 PL / 2BH², where

P = Load Fracture

L = Distance Pedestal

B = Width Test Objects

H = High Test Objects

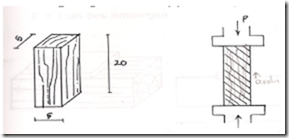

b) Examination of Courage Press Parallel Wood Fiber

Tools and materials required:

– Press machine with equipment

– Timber size of 5 x 5 x 20 cm

Inspection Method

– The breadth of the field of press timber (5 x 5 cm) F

– Put the test objects on a machine press

– Imposition is done continuously at the velocity of 0.008 cm long each test sample per minute.

– Reading of the load (P) and the deformation is done until it reaches a maximum.

– Calculate the firmness of wood fibers parallel press

![]()

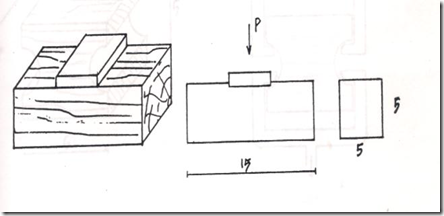

c) Determination Examination Perpendiculars Fiber

Tools and materials required:

– Press machines with supplies

– Ruler measuring / roller meter

– Iron slab 5 x 5 cm with a thickness of 5 mm

– Timber size 5 x 5 x 15 cm

Investigation Method:

– The test object is placed on the machine planers

– Put the plates 5 x 5 cm with a thickness of 5 mm above the test specimen is right in the middle.

– Charges pressed continuously, at a speed of 0.3 mm per minute, so the burden will work through the iron plate on wood radial field.

– Charges pressed against the specimen until urgent 2.5 mm iron plate.

– Determine the compressive strength perpendicular to the fiber.

d) Examination Strong Pull Perpendiculars Fiber

Tools and materials required:

– Engine drag

– Drill with Ø 2,5 cm

– Saws

– Wood with a size of 4 x 5 x 6 cm

Investigation Method:

– Place the specimen in the tensile tool in a tight squeeze on the tensile machine.

– Load is given continuously at a speed of 0.25 cm per minute.

– Test results are seen to rupture load (P) kg

– Calculate the perpendicular fiber tensile firmness

e) Examination of Parallel Fiber Pull Strength

Tools and materials needed

– Tensile machine and equipment

– Saws

– Sculpture wood

– Wood as in the picture

Inspection Method

– The test object enter the machine pull clamp

– The specimens were withdrawn continuously at a speed of 0.25 cm per minute

– Objects drawn up broke and kekuatannta (P)