In the rolling bearing rolling friction occurs between the rotating parts with the rest through the rolling elements such as balls (bullets), roller or needle roller bearings or spherical roller. Rolling bearings are more suitable for small loads. Round the rolling bearings is limited by the centrifugal force arising on the rolling elements. When viewed in terms of cost, rolling bearings are more expensive than plain bearings.

Anti-Friction Bearing used on rotating objects, to reduce friction and minimize friction bearing surface early on the price / flat. Anti Friction bearing consists of:

- Ball bearing

- Roller bearings,

- needle bearing

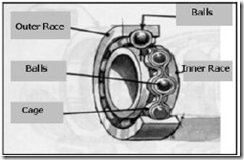

Anti-friction bearing is composed of several components, namely: Inner race Outer race, Balls or roller and Cage.

Figure 3.12 Bearing rolling

Figure 3.13 Components of rolling bearings

- Inner race or Cone: a hardened steel ring with a given groove to move the roller or ball on the outside, often mounted on a rotating shaft as a support bearing.

- Outer race: Outer race is almost the same as the Inner race, outer race is a hardened steel ring with grooves for the movement of the ball or the rollers inside.

- Balls or Rollers:

Among Inner races and outer race there is a component that serves to reduce friction carried out by balls, rollers or tapered rollers. Balls and Rollers are made of hardened steel. Balls or rollers move freely between the inner and outer race.

Figure 3.15 Inner races and outer race

Cage: Location of the cage between the inner race and outer race are used to keep the ball or roller distance with each other. Anti-Friction Bearing reduce the heat by reducing the contact area rubbing together. Balls have a contact point between the inner and outer race to hold the load so as to allow rotating at high speed. Lubrication oil film serves to separate components that are interconnected. Which includes Anti-Friction Bearings:

Straight Roller, has a line of contact, which enable to withstand the load Radial Load larger.

Figure 3.16 Straight Roller

- Tapered Roller, works the same way with the straight roller. Tapered bearing is often used at the end of a rotating shaft joint to withstand radial load and resist movement toward the left, the right shaft (Thrust Load).

- Needle Bearing works the same way with a straight bearing and tapered bearings with line contact. Because with a smaller diameter, needle bearings can be used in the application in narrow places.

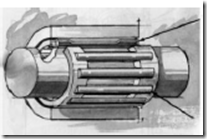

Caged Needle Bearing

Caged Needle Bearing lehih have the ability to load high compared to Needle bearing and its application is limited to a gap smaller than 10 inch (245 mm).

Figure 3.17 Caged Needle Bearing

Anti-Friction Bearing advantages:

- There is no wear on the shaft

- Minimized energy is wasted.

- Enables higher speeds.