The tools are relatively accurate grading by weight at a moderate pace and safe (does not cause material damage). Sorted materials can vary greatly in size and shape.

1) separator filter

The filter is combined with a blower or blowing is a widely used tool to separate the grains. Grains will pass through the filter and impurities such as twigs left on the filter, with the blower then dirt or other objects that pass through the filter along with the grain will be blown and separated because of lighter weight than the grains. Usually graded sieve to separate the dirt that size is smaller than the seeds and weighs more than the seed for example gravel that will pass through a sieve with small size.

Image sorting and grading tools in the form of multilevel filter is presented in the following figure.

Figure 15. Tool sorting and grading with multilevel filter

2) Pneumatic Separator

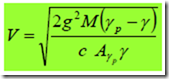

Sorting and grading tools that use air flow is often referred to pneumaticseparator. This tool works using the principle pengipasan based on weight differences grains and dirt. The determination of the flow velocity of wind / air is very important to determine the speed of the air used can be calculated by the following formula.

Where:

V = air velocity, ft / sec

M = mass of the particle, lb

p = density of particles, lb / ft

= density of air, lb / ft

A = area of the projection material, ft2

c = coefficient of friction of aerodynamic particle

g = gravitational (lb / ft2)

3) Separator density

Separator apparatus based on principle similar density dg pneumatic separator, the separation occurs because of differences in seed weight and heavy dirt. Horizontal movement of the tool sorting and grading will separate the dirt lightweight, seeds and dirt are heavy, heavy part opposite the greatest example seeds will be further catapulted at the top while the impurities specific gravity low to be separated at the bottom, airflow from below will help separate the parts.

4) Separator Ulir

Screw separator tool works by using the force of gravity and reflectance or lentingan of products, an energy-efficient appliance separator. This tool is used to separate the grains eg soya bean seeds. Vertical helix-shaped screw separator and in which there are several bulkhead to separate each of taip section. The part that most low specific gravity and low power pantulnya such as dirt and dust will be in the middle of the field, while the grains are separated also based on weight and power pantulnya. Good grain has better reflectivity anyway. This tool works quickly but results pemisahaanya sometimes still mixed among the parts to be separated.

5) Separator cylindrical

Sorting and grading tool cylinder in which there are two sections each with a screw driver to bring products that are sorted and grading. Seeds that have greater weight will tend to be at the bottom, while the seeds and dirt lighter located at the top and will go into the other room to be separated.

6) Separator disc-shaped

Sorting and grading tool consists of a cylindrical disc-shaped depressions in the surface of the cylinder to hold the grains. Basin will accommodate each grain seeds and will move to the other while the bigger dirt do not get carried away by the cylinder and will fall in other parts of dipiahkan.

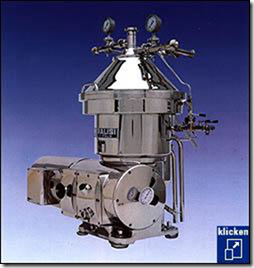

7) Separator with centrifugal

With a centrifugal separator or a centrifuge is a device sorting and grading the work of separation by weight of the particles by the centrifugal force. This tool is used to separate the commodity dibiasanya liquid eg cow’s milk. The centrifugal force will throw the particles with a higher weight to the outermost or farthest. Fresh cow’s milk can be separated into cream and skim section.

Skim part is the part that has a higher weight because it contains particles such as proteins, sugars and minerals, while the cream is part of the lower weight as much fat. Rotation speed greatly influence the outcome of the separation, the determination of the speed can be calculated using the equation stoke’s.

Figure 21. Tool sorting and grading system with centrifugal