The main function of the rotary system (rotating system) is to provide puataran the drill pipe circuit and also objected to the chisel in the drilled formation. Round sourced from round the rotary table (if using Kelly) or from the top drive motor rotation. The amount of the desired rotation is usually called Rotation Per Minutes (RPM). The magnitude of the load circuit drilling will provide a useful objection to aid in the breakdown of the rock drill bit during drilling operations in progress.

This burden is often called premises Weight On Bit (WOB). With the combination of the right RPM and WOB will produce optimum drilling speed (Rate of Penetration optimum).

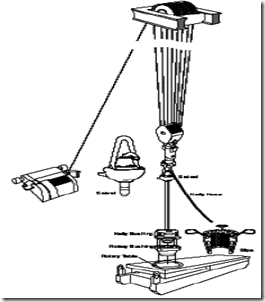

Figure 4.10. Playback system

The arrangement of the rotating system components can be seen in Figure 4.10. The main components of the lift system (rotating system), among others:

1. Swivel

2. Equipment swivel (Rotating Equipment)

3. The series of drilling (Drill Stem)

4. The drill (Bit)

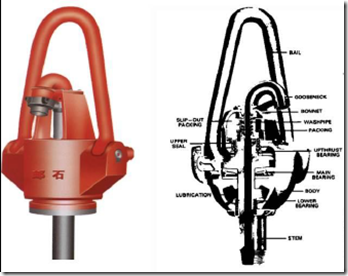

Swivel, the tool is mounted on the top end of the drill pipe and connect circuits directly with a rotary system and circulatory system (circulating system). This tool has several important functions, among others:

– Giving freedom to a series of drill pipe to rotate.

– As a liaison between the rotary hose with kelly sehinggamemungkinkan for circulating drilling mud without leaking.

– Connect the drill stem to the lifter system. Swivel attributed to the hook and the traveling block with swivel bail. Swivel must be able to withstand heavy loads during the drilling operation, drill stem and added load to the pull (pull over) when the drill stem pinched and others.

– Allow the rotary system (rotary system) rotate the drill rod (drill stem). Body / Housing swivel does not spin but hold swivel stem associated with kelly and drill stem below. Swivel Agency has units (bearing) to secure and regulate swivel movement, connected with kelly and drill stem is rotated by the turntable 35-200 RPM.

– Powering the high pressure drilling mud to the drill stem without leakage. Mud pressure of rotary hose, past the goose neck swivel, swivel wash pipe stem Assemblies and then go to kelly and drill stem below.

Figure 4.11. swivel

Parts of swivelini consists of: bail, gooseneck, washpipe assembly, bonnet, housing, rotating swivel stem and pin.Pada top drive, swivel mounted together with a top drive. Swivel can be seen in Figure 4.11. Swivel is made resistant to the danger of abrasion / erosion of the drilling mud. Resistant to leaks in the circulation pressure reached 4500 psi and can discharge up to 1000 GPM with a round drill stem reaches 200 RPM or more and also be able to withstand the load of more than 500 tons.

The drill, the end of a series of drill pipe that directly touch the formations, with the function to destroy and penetrate the formation, by weight on the drill bit. The types of drill bits: Drag Bit, Roller-Cone (Rock Bit), Diamond Bit

Figure 4.30. Drag Bit, Roller Cone Bits and Diamond Bit