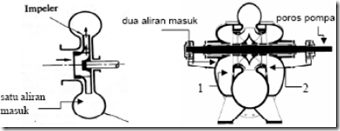

According to the number of the incoming flow, centrifugal pumps are classified into one inflow and two inflows. Single suction pump is widely used because of the simple construction. Problems on this pump, namely the axial force arising from the suction side, could be solved by adding ballast space, so no need to use large axial bearings. To pump two inflows widely used in large or medium-sized pump.

Construction of this pump impeller consists of two back to back and the liquid coming from both sides of the impeller, with such construction, the problem does not arise because the axial force balance each other. Discharge liquid out twice from the discharge liquid that goes through the two sides of the impeller. Pumps of this type can also be operating on high rotation. For inflows of more than two, the same principle works with two inflows.

Figure 3:56 Classification pump based on the number of inflows

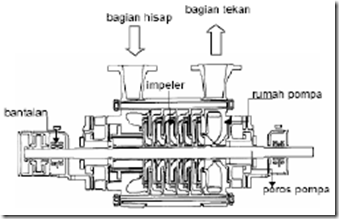

Figure 3:58 Pumps many levels (multistage)

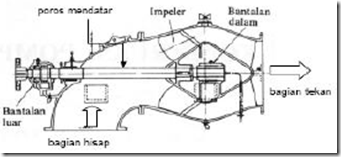

Based on the position of the shaft, pump divided into two horizontal and vertical pumps horizontal axis pumps have a shaft with a horizontal position. while the vertical shaft pump has a shaft in an upright position. Axial flow pumps and mixed lots made with the shaft upright. Fitted with a pump housing supported on the floor by pipeline to channel the liquid out of the pump. The position of the pump shaft is straight and mounted along the axis of the water pipe to the outside and connected with the motor on the floor.

The shaft is supported by several bearings, so sturdy and usually covered with casing pipe that serves to channel the lubricating oil. Pump shaft upright position based on the pump there are two kinds of pump wells are dry and wet sinks. Dry wells are installed outside the cistern pump suction, while the wet wells instead.

Figure 3:59 Horizontal Pump