If the cross-section of a field made up of a cross-sectional arranged symmetrically to the axis line, then the moment of inertia is a number or a reduction of the cross section composed penapang. For example, two squares forming a cross-hatched as shown in the picture, it is the moment of inertia Ix = Ix1 – Ix2. Stackable cross-section of ...

Read More »Hukum Newton

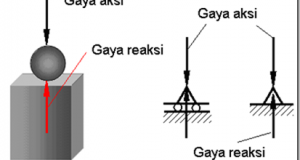

Dalam keadaan sehari hari sering kita jumpai hal hal yang berhubungan dengan hukum Newton, sebagai contoh: jika kita dalam kendaraan yang sedang berjalan tiba tiba kendaraan tersebut direm, maka seluruh isi kendaraan termasuk badan kita akan bergerak kedepan , atau sebaliknya jika kita sedang berdiri diatas bis yang sedang diam tiba tiba bis maju maka badan kita akan bergerak kebelakang. ...

Read More »Menjumlah Gaya Dengan Cara Lukisan

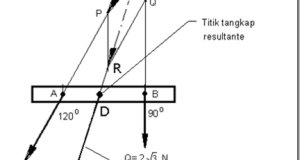

Jika ada dua buah gaya yang mempunyai titik tangkap sama dengan arah berlainan arah dari kedua gaya membentuk sudut α maka jumlah resultannya dapat dihitung dengan persamaan berikut : Gambar 2.23 Dua gaya dengan arah berlainan Untuk α = 90o maka Cos α = 0 atau berlaku rumus Phytagoras yaitu : Keterangan : o P dan Q = komponen gaya ...

Read More »Disposal and Installation Process

In outline, before removing and installing the components, it must first observe the following: 1. Type / type of machine (component) 2. Other components installed on the machine 3. Supplies of equipment and materials 4. Safe work area 5. Purpose of manual book Careful observation can actually help smooth your work, and otherwise carelessness and observation that will surely trouble ...

Read More »Magnetic Starter and Automatic

a. Magnetic Starter Magnetic starter is a term that is imposed on the starting of the motor circuits directly using contactors and thermal overload. Figure 2.17 shows an example of a large-capacity magnetic starter for mengasut a 3-phase motors. Medium Figure 2.18 shows the electrical diagram of a magnetic starter control circuit. Figure 2.17 Non-Reversing Starter Magnetic Control Figure 2.18 ...

Read More »Cidera Akibat Sengatan Arus Listrik

Sering kita mengira, bahwa bahaya tersengat arus listrik hanya dapat disebabkan oleh sirkit tegangan tinggi. ini tidak benar. Banyak kasus kecelakaan kerja tersengat arus listrik, yang berakibat fatal hingga sampai kematian diakibatkan oleh tegangan rendah 120 volt. Bila diantara kita pernah tersengat arus listrik tetapi aman-aman saja tidak mengalami akibat buruk, janganlah peristiwa tersebut dijadikan pegangan, mungkin anda sedang beruntung. ...

Read More »