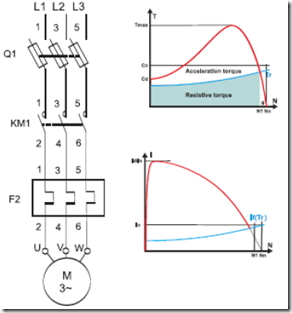

Motor operation protects against tampering and damage, on the applied control circuit protection equipment such as table 1. Reliability performance protection will determine motor protection against interference. As an illustration dipelihatkan in Figure 3-1, a circuit controlling a motor with two speeds and two-way swivel that is equipped with the tools and the TOL protection fuse or MCB.

Figure 3-1. The motor control protection system.

From Figure 3-1, the protection system has two control motors, each of which will protect the different currents, then the termination of the current limit setting is not as great.

Protection from voltage sources with fuse, both for the power circuit and to the control circuit. Fuse function can be replaced with MCB, see Figure 3-1. Reliability TOL (thermal over-load) as a means of protection is the amount of protection current can be set refers to the motor nominal current.

Contactors magnet of Figure 3-1, in addition to a switch, also functions as a zero-voltage protection. Wherein when no voltage to the coil, then the contactor will break the connection to the load. This will occur if the control system lightning.

Grounding Motor

Grounding system an electric motor as shown in Figure 3-2, is the equipment of motor protection against touch voltage and lightning strikes. If the earthing cable binder bolt of figure 3-2, is not bound fast ignition will occur when the body touched the motor voltage insulation failure caused by a motor or motors being struck by lightning.

![image_thumb [1] image_thumb[1]](http://www.tneutron.net/elektro/wp-content/uploads/sites/2/2016/01/image_thumb1_thumb.png)

Figure 2-2. Grounding cable Motor

Bond due to imperfect grounding bolt-resistance grounding big plus, if the motor body touched voltage as mentioned above and the motor body was touched by humans, it is not a good grounding voltage will flow through the human body, which amount may berakibatkan fatal. Therefore, check the earthing cable motors, especially firmness bonding cable connections as shown in Figure 3-2. Good grounding magnitude was 0.8 Ω maximum custody.