Safety device used on the motor occurs when the load is called the Thermal Over Load Relay (TOR / TOL) is usually coupled with a contactor, the market there is also a more integrated security burden on Motor Circuit Breaker. Relay is normally connected to the contactor to the main contact 2, 4, and 6 before being connected to the load (motor). Useful to provide protection against the motor from damage due to overload.

Some causes of overload are:

- Too magnitude of mechanical load on the motor.

- Starting current is too large or the motor stops suddenly.

- The opening of one phase of a 3-phase motors.

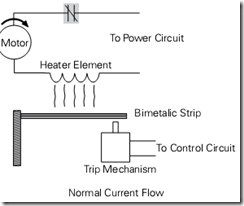

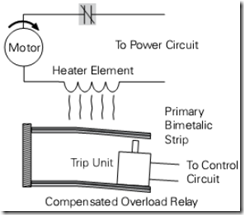

Currents that are too big arise on the motor load will flow to the motor windings which can cause damage and burning of motor windings. To avoid this happening mounted Thermal Over Load Relay (TOR / TOL) in the control circuit. The working principle Thermal Over Load Relay (TOR / TOL) by heat (temperatures) generated by the current GCC flowing through the heating elements bimetal, which menakibatkan bimetal curving will then move contacts mechanical circuit breaker electrical contacts 95-96 open and contacts 97-98 closes.

Figure 5-5. TOR under normal circumstances.

Figure 5-6. TOR in a state of overload.

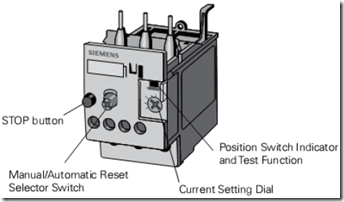

Picture 5-7. Construction Thermal Over Load Relay (TOR / TOL).

Other equipment from thermal overload is a mechanical reset function to restore the contact position 95-96 in its original position (connect in normal circumstances) and contact 97-98 (open under normal circumstances). After the reset button is pressed, the contacts 95-96 which was originally opened as a result of the load will re-close and contact 97-98 will be re-opened. Another part of the thermal overload is the current limit regulator.