Persyaratan peralatan produksi. Adanya petunjuk penggunaan peralatan. Peralatan dapat digunakan sesuai fungsinya Tidak membahayakan makanan dan pekerja. Bagian peralatan yang kontak langsung harus halus, rata, tidak berlubang, tidak mengelupas. Pencegahan terhadap kontaminasi dari baut, pelumas, bahan bakar dan lain-lain. Alat mudah dibersihkan dan didesinfeksi khususnya yang kontak langsung dengan bahan/makanan. Peralatan terbuat dari bahan yang tahan lama, tidak beracun (contoh ...

Read More »Use of Potassium Permanganate (KMn04)

Based on this research, it turns bananas Mas require ethylene absorbent substance and should be stored in refrigeration units for durability remain green until 6 weeks. Various forms of ethylene absorbers that have been tried, such as block vermiculate and cement mixture with a ratio of 3: 1 are dipped in a solution of KMn04, or blocks a mixture of ...

Read More »Fruit Physiology

Physiology of fruits is very important to know for the purpose of handling and processing. Physiology fruit with regard to the following aspects: growth and respiration processes such as maturation, kelayuan (senescence), klimaterik, and the role of ethylene in fruit ripening process. a. The process of growth and respiration Stages of fruit growth process generally include cell division, cell maturation ...

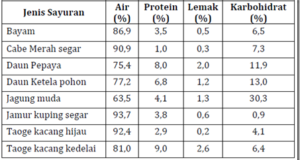

Read More »Kandungan Gizi Sayuran

Sayuran merupakan kelompok komoditas pangan yang pada umumnya sangat banyak dikonsumsi oleh masyarakat, baik sebagai sayuran mentah (lalapan) ataupun dengan cara dimasak terlebih dahulu. Mengonsumsi sayuran memberi sumbangan terutama vitamin A dan C, serta serat yang sangat penting bagi tubuh. Sayuran diklasifikasikan sebagai tanaman hortikultura. Umur panen sayuran pada umumnya relatif pendek (kurang dari satu tahun) dan secara umum bukan ...

Read More »Understanding Carbohydrates (Starch)

Carbohydrates by plants kept in the fruit for the supply of energy which is then used to carry out the activity of the rest of his life, so that in the process of maturation of the content of carbohydrates (starches) and sugar are always changing. Changes starch in fruits can be divided into: a. Fruits with high starch content Changes ...

Read More »Peranan Etilen Pada Buah-buahan

Etilen dapat dihasilkan oleh jaringan tanaman hidup pada waktu-waktu tertentu. Etilen juga merupakan suatu gas yang dalam kehidupan tanaman dapat digolongkan sebagai hormon yang aktif dalam proses pematangan. Disebut hormon karena memenuhi kriteria sebagai hormon tanaman yaitu bersifat mobil (mudah bergerak) dalam jaringan tanaman dan merupakan senyawa organik. Etilen dapat menyebabkan terjadinya perubahan-perubahan penting dalam proses pertumbuhan dan pematangan hasil-hasil ...

Read More »